A Beginner’s Guide to Dual In-line Package (DIP): An Overview of Its Uses and Benefits

- Shariq Hussain

- December 27, 2022

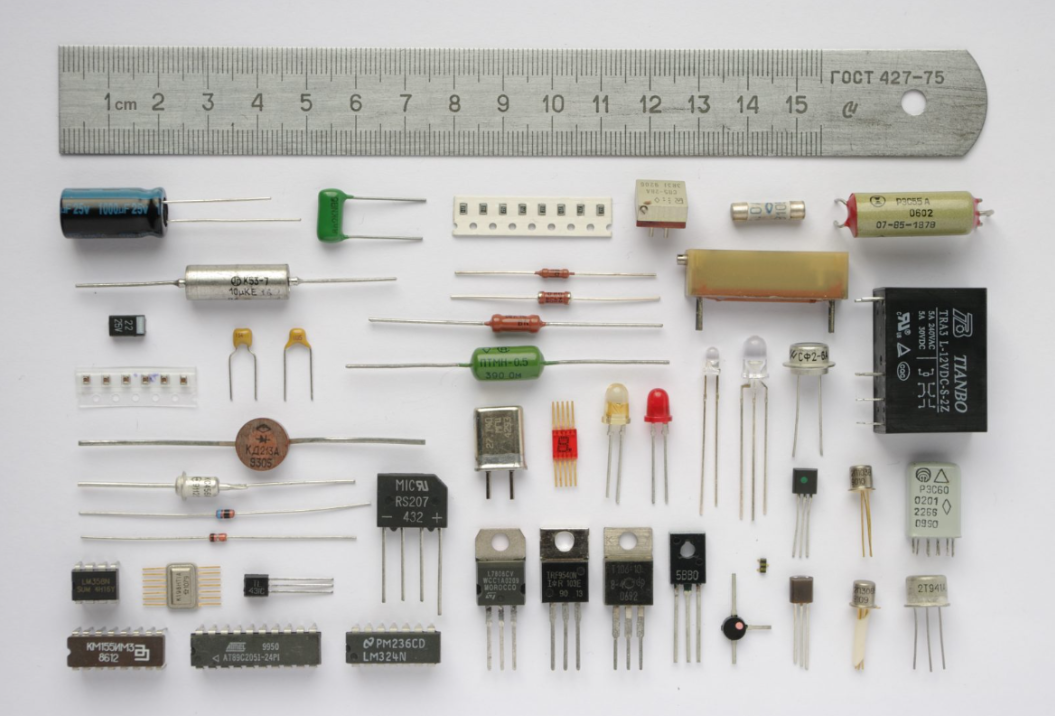

Dual In-line Package, or DIP, is a type of integrated circuit package that is used to connect a printed circuit board (PCB) to the components inside the circuit. DIP is a versatile and easy to use package that can be used for a wide range of applications, including data processing, communications, and control systems.

It has a wide range of advantages, including being low cost, easy to assemble, and reliable. This beginner’s guide to DIP provides an overview of its uses and benefits, so you can decide if it is the right choice for your next project.

What is Dual In-line Package (DIP)?

DIP Assembly is a type of integrated circuit (IC) packaging that comes in a plastic or ceramic housing that holds the IC components side by side in rows within a two-row mounting frame or socket. DIP is very common in electronics and is used to connect a printed circuit board (PCB) to the components inside the circuit.

It has a wide range of advantages, including being low-cost, easy to assemble, and reliable. DIP stands for the “Dual In-line” design. This refers to the fact that the IC is placed side by side on a Printed Circuit Board (PCB). It’s also referred to as “pin-in-hole”, since the IC is mounted on the PCB by inserting its leads through holes in the PCB.

Advantages of DIP

The advantages of DIP make it an excellent choice for a wide range of applications. It is low cost, easy to assemble, and reliable, with a high degree of standardization and a wide range of parts availability. There are also no alignment issues and no matching requirements, with all parts having a fixed value.

It also has a large range of voltage and current ratings, with a wide temperature range, making it suitable for a variety of environments. There are also no alignment issues and no matching requirements, with all parts having a fixed value. It also has a large range of voltage and current ratings, with a wide temperature range, making it suitable for a variety of environments.

Common Uses of DIP

DIP is used for a wide range of applications, including data processing, communications, and control systems. DIP can be used in a variety of ways, depending on the type and quantity of the components included in the circuit. DIP can be used in a variety of ways, depending on the type and quantity of the components included in the circuit. It is most commonly used as a general-purpose IC package that is easy to assemble and connect. This makes it suitable for a wide range of applications.

Design Considerations for DIP

There are a few things to keep in mind when designing a circuit board that uses a DIP. The first is the length of the leads, which are typically between 0.5 and 1 inch. This is important to account for the size of the circuit board and the space between the rows of components. The second consideration is the width of the IC. Generally, the width of a DIP is between 2 and 10 times the diameter of the IC.

The third and final consideration is the number of leads (pins) on the IC. The most common is 8 leads and 16 leads. You also need to consider the spacing between the pins. The best way to determine the spacing is to mark the exact location of each pin and use a ruler to find the exact distance between them. From there, you can add a little extra room to account for errors.

How to Assemble a DIP

DIP components can be assembled to a PCB by mounting them on the surface, or they can be inserted into holes. In both cases, the ICs are oriented so that the pins lie in rows at the same level as the surface or below the surface. The ICs are mounted and soldered to the PCB. To mount components on the surface, you can use a flat-surface DIP, which allows you to place components on the top and bottom.

This is a good solution for simple circuits with few components. DIPs can also be mounted on edge strips or PCBs. Edge mounting is often used to make room for other components on the PCB and is especially useful when building large boards with many components.

Common Types of DIP

There are many different types of DIPs available. Common types of DIPs include Standard DIP, Miniature DIP, and Micro DIP. Standard DIP is the most common and general-purpose package, used in most circuit applications. Miniature DIP is smaller than Standard DIP, but has the same pin arrangement.

It is commonly used in low-power applications, such as in low-current signal generators and oscillators. Micro DIP is also smaller than Standard DIP, but has a different pin arrangement that orients the pins in rows along the length of the package. Micro DIP is commonly used for low-power integrated-circuit applications and for high-density circuit boards.

Applications of DIP

DIP is used for a wide range of applications, including data processing, communications, and control systems. DIP can be used in a variety of ways, depending on the type and quantity of the components included in the circuit.

It is most commonly used as a general-purpose IC package that is easy to assemble and connect. This makes it suitable for a wide range of applications. DIPs can also be mounted on edge strips or PCBs.

Edge mounting is often used to make room for other components on the PCB and is especially useful when building large boards with many components.

Benefits of DIP

The advantages of DIP make it an excellent choice for a wide range of applications. It is low cost, easy to assemble, and reliable, with a high degree of standardization and a wide range of parts availability. There are also no alignment issues and no matching requirements, with all parts having a fixed value.

It also has a large range of voltage and current ratings, with a wide temperature range, making it suitable for a variety of environments. There are also no alignment issues and no matching requirements, with all parts having a fixed value. It also has a large range of voltage and current ratings, with a wide temperature range, making it suitable for a variety of environments.

Disadvantages of DIP

The advantages of DIP make it an excellent choice for a wide range of applications. It is low cost, easy to assemble, and reliable, with a high degree of standardization and a wide range of parts availability. There are also no alignment issues and no matching requirements, with all parts having a fixed value.

It also has a large range of voltage and current ratings, with a wide temperature range, making it suitable for a variety of environments. There are also no alignment issues and no matching requirements, with all parts having a fixed value. It also has a large range of voltage and current ratings, with a wide temperature range, making it suitable for a variety of environments.

Conclusion

DIP is a type of integrated circuit package that is used to connect a printed circuit board (PCB) to the components inside the circuit. DIP is a versatile and easy to use package that can be used for a wide range of applications, including data processing, communications, and control systems.

It has a wide range of advantages, including being low cost, easy to assemble, and reliable. This beginner’s guide to DIP provides an overview of its uses and benefits, so you can decide if it is the right choice for your next project.